Contact Us

Lishuangdian Industrial Zone, Zhengding County, Shijiazhuang City, Hebei Province, China.

info@hsspcflooring.com

Whatsapp/Wechat: +86 15933619081

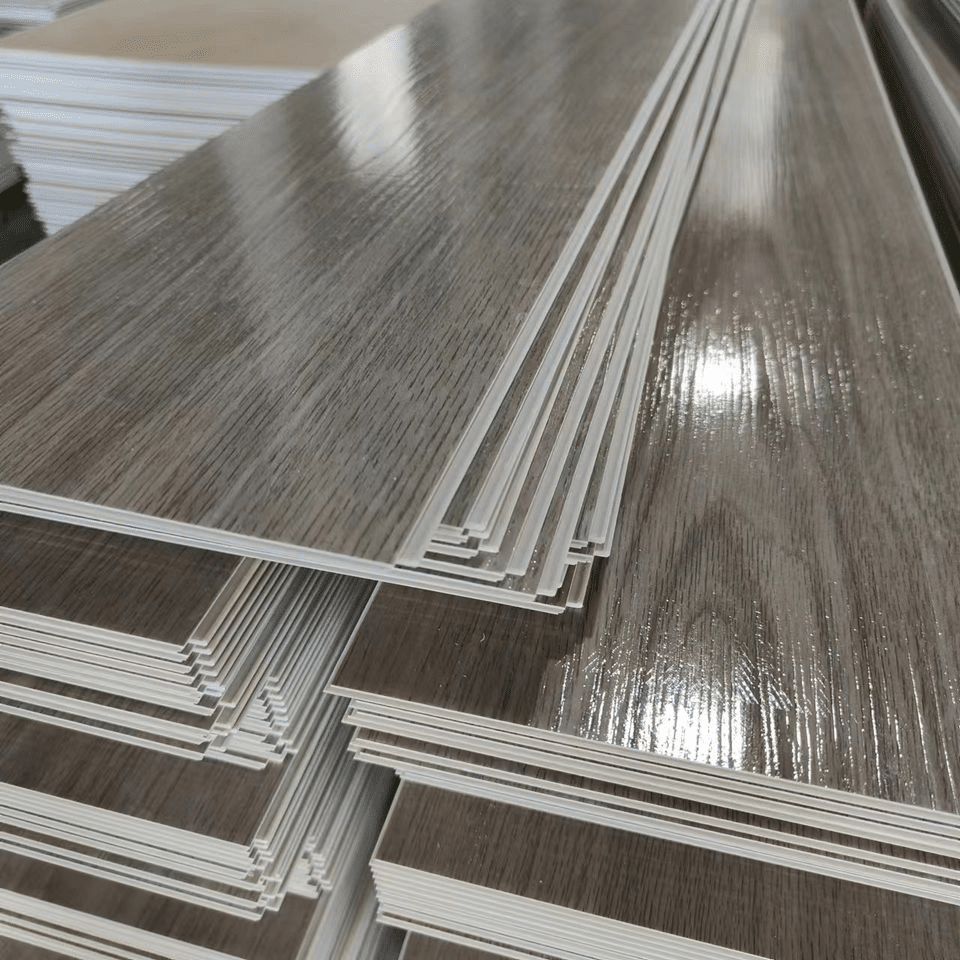

In recent years, SPC flooring (Stone Plastic Composite flooring) has gained worldwide recognition thanks to its outstanding performance and wide range of applications. Global demand continues to grow year after year, as SPC flooring combines durability, waterproof performance, design flexibility, and easy installation.

From residential homes to commercial spaces, SPC flooring can now be found almost everywhere. It realistically replicates wood grain, stone, tile, and even carpet textures, and can be installed in modern patterns such as herringbone layouts. Due to its excellent water and moisture resistance, SPC flooring is increasingly used in kitchens, bathrooms, basements, and even garages.

However, as applications expand, expectations for scratch resistance and wear performance have become significantly higher—especially in high-traffic and demanding environments.

We previously discussed this topic in our article “Why SPC Flooring Is Not Thicker Is Better”. Many buyers still mistakenly believe that thicker SPC flooring automatically means better wear resistance. This assumption is incorrect.

Traditionally, wear resistance has been closely associated with the wear layer thickness of SPC flooring, which typically ranges from 0.1mm to 0.7mm. Under the same conditions, a thicker wear layer does provide better resistance to abrasion.

However, even SPC flooring with a thick wear layer can suffer from rapid scratching, visible abrasion, and surface damage when exposed to:

In extreme cases, excessive surface wear can even lead to direct damage to the flooring, negatively affecting appearance, functionality, and user experience.

Based on extensive customer feedback over the past year, especially from markets with strict requirements for scratch resistance and surface durability, we identified a clear demand:

SPC flooring that does not rely solely on wear layer thickness, but achieves fundamentally higher scratch resistance.

To address this challenge, we invested in thousands of material tests and process trials to develop a solution that works at the source—not just on paper specifications.

The key to truly ultra-scratch-resistant SPC flooring lies in surface technology, not simply thickness.

We have developed and adopted a specially treated, advanced UV coating system that significantly enhances:

This UV coating process is highly complex and technically demanding, requiring precise control of materials, curing methods, and application parameters. The core breakthrough of this ultra-wear-resistant technology lies in the UV coating formulation and treatment process itself.

As a result, this SPC flooring delivers:

At present, this technology places us at the forefront of ultra-wear-resistant SPC flooring development.

Our ultra-scratch-resistant SPC flooring has already been exported to multiple demanding markets, including:

Customer feedback from these regions has been extremely positive, particularly in:

Clients consistently report significantly improved scratch resistance and long-term surface performance compared with conventional SPC flooring.

This advanced SPC flooring solution is especially suitable for:

It is not just “wear-resistant on paper,” but engineered for real-world, demanding use.

As SPC flooring applications continue to expand, traditional approaches relying only on thickness or wear layer numbers are no longer sufficient. True durability requires innovation at the material and surface-engineering level.

Our ultra-scratch-resistant SPC flooring, developed through advanced UV coating technology and extensive testing, offers a new benchmark for durability, aesthetics, and performance in high-wear environments.

If you are looking for truly ultra-wear-resistant SPC flooring, we welcome you to contact us for further discussion. Samples can be arranged for evaluation, so you can experience the performance difference firsthand.